1Froth flotation Cyanidation This method is most commonly used for gold-containing quartz dike. A concentration of 2530 is suitable for economical smelting of copper.

Froth Flotation Process Detailed Explanation With Diagrams And Videos

In some cases for example sulphides ores of copper.

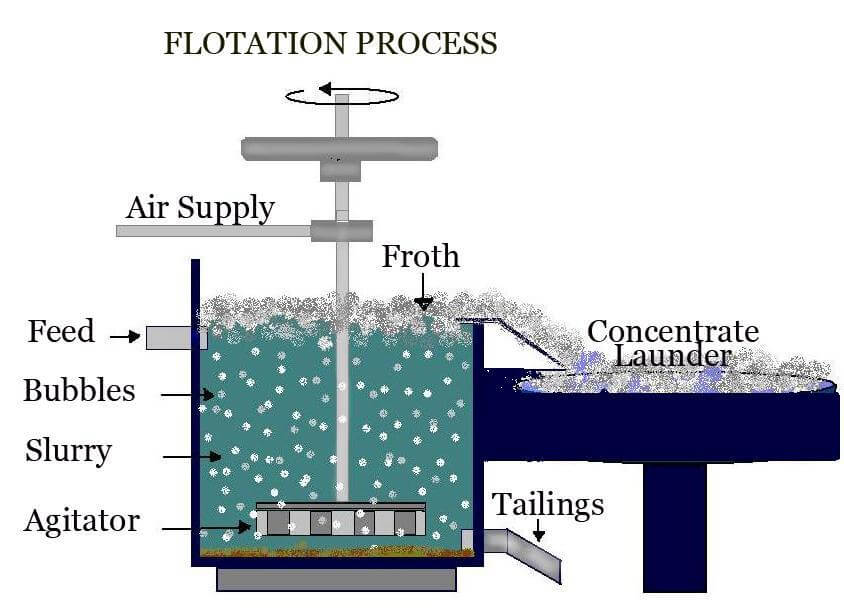

. Froth flotation is a process that selectively separates materials based upon whether they are water repelling hydrophobic or have an affinity for water hydrophilic. The principle behind froth flotation process is that sulphide ores are preferentially wetted by pine oil whereas gangue articles are wetted by water. Especially for sulfide ores.

1 Froth Flotation Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineralwater slurry. And 2 to aid in the selection of the particles of mineral of metallic resinous or adamantine luster in. The cleaner tailings return to the rougher flotation.

The analytical profile of the entire flotation circuit is. A Explain what froth flotation is and give five factorsreasons that make it important in ore processing b Different classes of reagents are used in the flotation process. It is a two-stage process that involves one rougher stage and one cleaner stage.

The FLOTATION PROCESS is one of the commonest methods of extracting the valuable minerals from certain classes of ores and it is generally more efficient as regards the recovery of the minerals than any other process applicable to. In these cases the initial ore could contain between 01-05 of the desired metal or mineral and following the flotation process the grade can increase to 20-25. Froth flotation machine is generally used for the concentration of sulphide ores.

Here are several combined process used for gold extraction according to different ore properties. Both stages are nonreactive unit operations that operate at steady-state. 1321 Ore Beneficiation by Froth Flotation.

As a very important mineral processing technology froth flotation is widely used for the separation of fine minerals. The flotation process for the concentration of ores is a method by means of which one or more of the minerals in the ore usually the valuable ones are picked up by means of a liquid film and floated at the surface of a mass of fluid pulp. Phosphate ore is divided into siliceous phosphorite calcareous phosphorite and siliceous phosphorite according to the chemical.

Concentrate regrinding middling regrinding and tailings regrinding process. The particles with attached air bubbles are then carried to the surface and. Importantly the word flotation is also used in the literature to describe the process in density separation in which lighter microplastics float to the surface of a salt solution.

This process is mainly used to deal with the ore with more complex grain size of useful minerals or the ore with mud in the grinding process. This is used in mineral processing paper recyclingand waste-water treatment industries. For quartz-type fluorspar ore the main focus is on silicon reduction in the concentrate.

Froth Flotation Process of Different Types of Fluorite Ore 1. Froth flotation process which is used for the concentration of sulphide ore. The stage froth flotation is divided into three forms.

A froth flotation process is used to concentrate copper ore. Because of the nature of the phosphate ore such as mineral types and content disseminated particle size its separation difficulty and flotation types varies. Here they are separated from the other minerals which remain immersed in the body of the pulp.

Uses sodium ethyl xanthate C 2. The froth handling in the flotation process-unusual solutions for usual problems April 14 2021 by Ames Flotation is a widely used process in the beneficiation of metal ores. Froth flotation process is used for the A Oxide ores B Sulphide ores C Chloride ores D All of these Medium Solution Verified by Toppr Correct option is B Only sulphide ores are concentrated by froth flotation process because pine oil selectively wets the sulphide ore and hence brings it.

It has been described as the single most important operation used for the recovery. It is effective for the concentration of low-grade and multicomponent ores in cases where other methods of separation are not technically feasible. Froth Flotation of Quartz Fluorite Ore.

Explain the roles of the following reagents and give an example of each class. Froth flotation is a process for selectively separating of hydrophobic materials from hydrophilic. In this process the suspension of a powdered ore is made with water.

Historically this was first used in the mining industry where it was one of the great enabling technologies of the 20th century. Froth flotation is used to raise the low mineral concentrations in ores to concentrations that can be more economically processed. The combined process between froth flotation process and other processes can usually achieve impressive results for different types of gold ore.

Froth flotationis a process for selectively separating hydrophobic materials from hydrophobic. For fine-grained embedded quartz-type fluorite ore generally use oleic acid or oxidized paraffin soap as a collector sodium carbonate as a pulp PH conditioner sodium. The purpose of the oil in froth-flotation is 1 to form together with the water and solid of the pulp and the gas introduced into the pulp a froth.

Froth flotation is one of the steps which is generally performed before. In general the minerals which. Generally we say fine mineral refers to mineral particle size less than 18 m or less than 10 m ore mud.

It is a metallurgical process for the extraction of metals in a pure state from their ores. However the froth flotation process is also used to extract coal iron potassium chloride phosphates and in the paper recycling industry for deinking paper fibers. Froth flotation is the most widely used phosphate ore separation process.

Is based on the difference in wettability of different minerals. Froth Flotation is commonly employed in mineral processing. Froth flotation process which is used fo.

Sulphide Ore Is Concentrated By The Method 1 Froth Flotation Process2 Magnetic Separation3 Gravity Method4 Calcination Method

Froth Flotation Process Detailed Explanation With Diagrams And Videos

Explain The Purification Of Sulphide Ore By Froth Floatation Method

0 Comments